The Benefits of Working with a Leading Control Panel Supplier

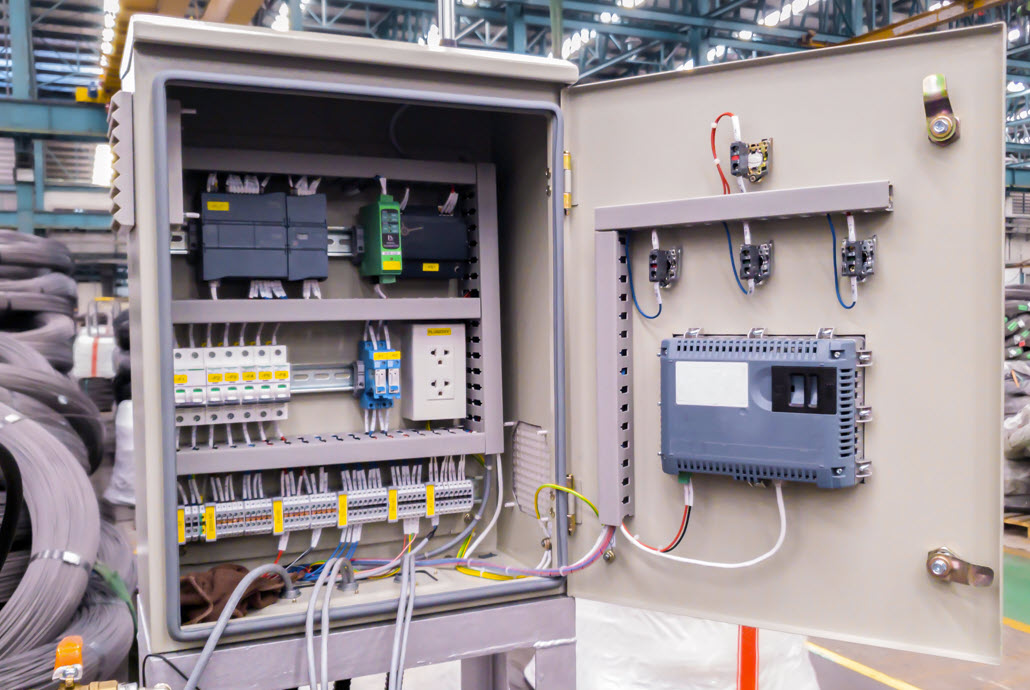

Industrial pros know that in this fast-paced world, automation and precision are king – and that makes control panels truly unsung heroes. After all, these components work hard to direct machinery operation and ensure everything runs smoothly and safely.

But behind every dependable control panel is a knowledgeable supplier who helps you find the best options on the market. When you partner with a reliable supplier of control panels, you gain more than just a product – you gain access to expertise, quality assurance, and solutions tailored to your unique needs.

Already know the value of finding a control panel supplier with a rock-solid reputation in the industry? Check out your control panel options here.

What Can a Supplier of Control Panels Do for You?

The right control panel supplier can connect you to a wide range of panels manufactured by leading companies. These suppliers act as intermediaries, helping your company navigate the overwhelming variety of options to find panels that meet your exact specifications.

Control panels play essential roles across industries, housing the electrical components that drive machinery and processes. Whether it’s a factory floor, a healthcare facility, or a renewable energy installation, these panels are essential to maintaining functionality and safety.

Suppliers go beyond simply providing options – they bring industry knowledge and relationships to the table. This expertise ensures you’re not just getting a control panel but the right control panel for your systems, with compatibility and compliance guaranteed.

Sourcing From Leading Manufacturers

Suppliers typically collaborate with multiple manufacturers to offer a comprehensive selection. This allows them to provide access to specialized solutions, from standard models to highly customized designs. In other words, their role bridges the gap between your needs and manufacturers’ capabilities.

Why Partnering With a Trusted Supplier Matters

As we’ve already alluded to, a reliable supplier of control panels is more of a strategic partner than simply a vendor. By curating high-quality control panels from multiple manufacturers, they can offer you unmatched versatility and flexibility.

This means you’re not limited to the offerings of a single company. Rather, you gain access to a broader array of options suited to your unique operational requirements and circumstances. And that’s important in an industrial world, where one size certainly does not fit all!

Ensuring Quality and Compliance

The quality of a control panel directly impacts a variety of areas, such as safety, operational efficiency, and equipment longevity. A reputable supplier only works with manufacturers that prioritize certifications like UL (Underwriters Laboratories) or ISO (International Organization for Standardization), thereby ensuring every product meets rigorous industry standards.

Inferior panels can lead to costly downtime, safety risks, and even legal compliance issues. With a trusted supplier, you can feel confident that your control panels will perform reliably, even in the most demanding environments.

Expert Guidance Throughout the Process

Navigating the world of control panels can certainly be daunting. With so many manufacturers and options available, how do you choose? That’s where the expertise of a supplier truly shines. They take the time to understand your needs and can then guide you to the ideal panel that balances performance, durability, and cost-effectiveness.

Whether you’re upgrading an existing system or building a new one from scratch, the right supplier can help you avoid costly mistakes and ensure seamless integration.

The Importance of Customization

Every facility has unique challenges, and control panels must adapt to these demands. Suppliers simplify the process of finding custom solutions by leveraging their relationships with manufacturers who specialize in tailored designs.

For example, some facilities operate in extreme environments, requiring panels that can withstand high temperatures, humidity, or corrosive conditions. Others may face space constraints, necessitating compact or modular designs. A supplier with access to a variety of manufacturers can meet your unique operational needs and connect you to the perfect solution, regardless of your requirements.

Supporting Smart Technology Integration

As industries continue to adopt smart technologies, the demand for control panels that integrate seamlessly with IoT systems is on the rise. Suppliers have an important role to play in sourcing panels equipped with advanced features like remote monitoring, predictive maintenance capabilities, and enhanced data collection.

By offering smart technology options, suppliers help ensure that your control panels don’t just meet baseline requirements – they enhance your operations and support future growth.

What to Look for in a Control Panel Panel Supplier

Choosing your parts supplier is the key step in ensuring your control panels deliver optimal performance. Here are some important considerations to keep in mind:

- Diverse Offerings. A wide selection of products from various manufacturers means more options to find the right fit.

- Industry Expertise. Look for suppliers with a proven track record in your industry. Their insights can help you make better decisions.

- Commitment to Quality. Verify that the supplier only works with manufacturers who meet high standards for safety and performance.

- End-to-End Support. A good supplier offers guidance throughout the purchasing process, from selecting panels to ensuring successful installation.

Applications Beyond Manufacturing

Of course, control panels aren’t just for manufacturing. They are essential across a broad range of industries. Suppliers who understand these diverse applications can help customers from various fields find the perfect solutions.

Some examples of other applications are:

- HVAC Systems. These include panels designed to regulate heating, ventilation, and air conditioning in large buildings.

- Renewable Energy Installations. These may be panels for solar farms or wind turbines that must withstand harsh outdoor environments.

- Smart Building Technologies. These are advanced panels for modern facilities integrating IoT and automation features.

The Long-Term Benefits of a Reliable Partnership

The value of a parts supplier can extend far beyond the initial purchase. Suppliers that prioritize customer success often offer ongoing support. Your needs will likely vary from someone else’s, but areas of support can include technical assistance, upgrades and replacements, and maintenance insights.

Troubleshooting and guidance for optimal panel performance will help you get the greatest value. Similarly, you may appreciate supplier recommendations that enable you to stay ahead of upcoming technological advancements and tips for extending your control panel’s lifespan.

As you can see, this partnership approach helps ensure your systems remain efficient, reliable, and compliant for years.

Finding the Right Supplier of Control Panels

In a world where reliability and efficiency are paramount, choosing a knowledgeable supplier for control panels can be a game-changer. By prioritizing quality, industry expertise, and a wide selection of products, your systems will continue to operate safely and efficiently.

When evaluating control panel suppliers, consider their range of offerings, their partnerships with reputable manufacturers, and their ability to provide customized solutions. With an experienced supplier like ACI Controls by your side, you’ll not only save time and effort but also gain peace of mind knowing you’ve invested in the best products available!